Multi Pass Stenter, Tension Less Dryer & Squeezer

- County of Origin: Italy

- Manufacturer: Alea

Alea was established in the 1881 as a company operating in the field of silk and wool drying, the most promising industry towards the end of the century in the region. Then the company is able to acquire a great level of specialization to meet the demand of a production system based on many small and scattered producers.

Alea is Famous for Specialised Drying Technology. Alea Manufacture Multi Pass Stenter Frame (Vertical Shap) And All types of Special Drying Mechineries.

In the fifties, the reconstruction turns the textile system in an organized group of companies, man made fibers come in use and again Alea is able to support their production by supplying new types of dryers, for yarn, staples and for the heatsetting of a large variety of fabrics styles.

In the sixties, the company is leading in Italy and towards the end of the decade, she turns to foreign countries: these are growing bigger and the projection of their economies is very interesting.

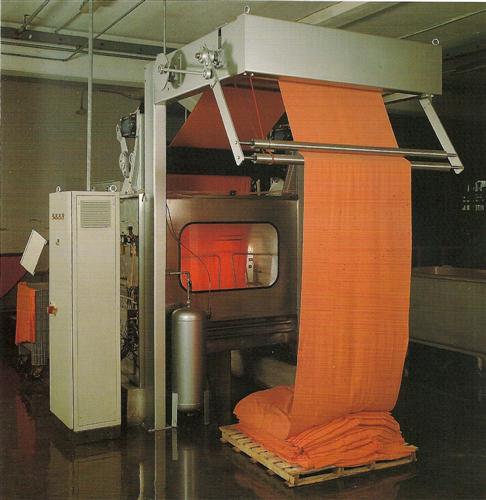

Alea multipass Stenter Frame

Space saving: Alea 11 layers Stenter is 23 meters long only ( including padder and weft straightener).

To get the same production with a single pass stenter frame, you have to buy a 12 chambers single pass stenter, that is 53 meters long. This is not only a huge waste of room but makes very difficult for the inlet operator to go to the exit for checking how the fabric is coming out.

Production: Alea 11 layers stenter gives the same production of 12 chambers Single Pass stenter. ( more than 15 Ton) . This is valid when the customer has to just dry the fabric. When the customer wants to heatset the fabric, the Alea 11 layers production is even more than a 12 chambers Bruecker single pass stenter.

This is the reason: the heat setting operation is obtained just by means of dwelling time of fabric in the hot chamber. (for example 45 seconds dwelling time at 190°), consequently the higher is fabric content, the faster the speed at the same dwelling time.

As Brueckner 12 chambers have only 36 meters of fabric content ( 3 meters x 12 chambers = 36 meters ), of course, will run at half the speed of 11 layers Alea that has 71 m. fabric content.

Sometimes this bigger production of Alea in heatsetting is in excess for customers requirement so they go at lower speed ( for example 60 seconds instead of 45) and lower temperature ( for example 170° instead of 190°).In this way the heatsetting of cotton/lycra takes place in a much better way.

Power Saving

Power saving is one of the great advange of Alea. Alea Has 88 kw only for 11 layer against 192 kw of 12 chamber bruckner stenter

Better Quality- Hand Feeling

Alea gives better quality hand and shrinking on fabric thanks to soft dyeing with low temperature and low air speed.

Cleaning System

Alea can be supplied with Automatic Filter cleaning system that give Effiency.

One more advantage of Alea stenter is that it is 100% made in Italy.

Detwister-Squeezer AS/CA

The detwisters-squeezers type AS/CA have given great benefit in the processing of tubular knitted fabrics between the dyeing and drying operations. Fabric handling is reduced considerably compared to traditional methods such that the only manual operation required is the sewing together of adjoining fabric pieces.

Additional processing benefits are achieved with the AS/CA with its provision for fabric straightening and the facility for addition of certain finishes in the wetting out bath.

The AS/CA machine, available in several models, can perform the following functions:

remove fabric twisting arising during dyeing

provide uniform water distribution prior to squeeze

enhance the appearance of the knitted loop structure by the air injection and balloon inflation system

present tubular fabric in spread plainted form ready for drying

overcome fabric creasing caused in traditional hydroextraction by centrifuge.

Options

The machine can be supplied with standard rubber squeeze rollers or rollers with special covering for improved hydroextraction.

Machine can be supplied with or without fabric expanders.

Machine can be supplied to process single rope or two ropes in parallel.